The Subcooled Air knowledge base is a good place to start if you want to get a better understanding of our products, have a problem related to dehumidification, or a question about one of our products. You can check the list of terms and explanations as well as questions from our clients and our answers.

If you cannot find an answer, please send us an email or give us a call. We will be updating our knowledge base continually.

Knowledge Base / FAQ

A set point is "the [temperature] point at which a thermostat has been set".

Dew point temperature correlates to the amount of water in the air. If humidity control equipment is working properly, the dew point temperature of supply air will be lower than room dew point temperature (Tom Dillon in Marijuana Venture)

Is the mass of water vapor divided by the mass of dry air in a volume of air at a given temperature.

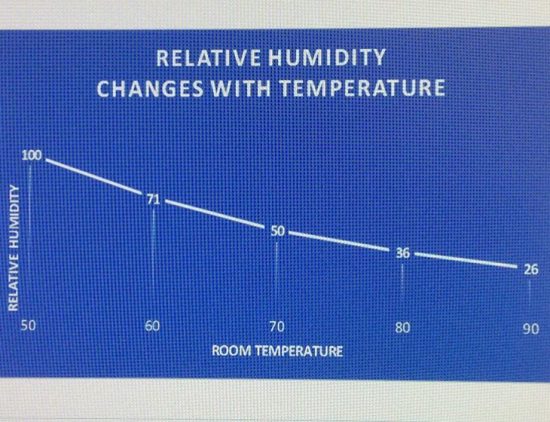

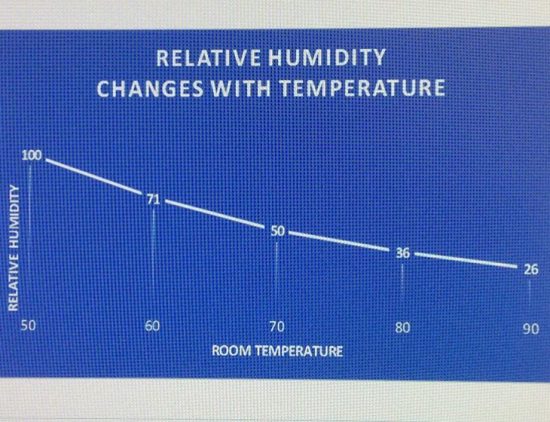

Is the amount of moisture in the air divided by the maximum amount of moisture that could exist in the air at a specific temperature. Rising room temperature lowers relative humidity.

Grow Room Climate Control - click here to download this article as a pdf.

A 2017 Energy Study states that 51% of indoor cannabis grow room energy use is associated with environmental climate control. Climate control efficiency directly affects your monthly electric bill.

Separating heat loads into sensible and latent components provides a basis to review efficiencies of different HVAC and dehumidifier systems.

Air conditioner performance looks at “Useful Heat”. This term covers cooling, condensing duty or heat delivered by an air conditioner/heat pump. Useful Heat divided by power input gives a Coefficient of Performance (COP) rating for the equipment. If an a/c delivers 12,000 Btu’s (1 ton) of cooling (and condensing) and uses 1 kW of power, the COP is 12,000 Btu’s per kW (or 3.51 Btu’s/Btu). Room heat is reduced by 12,000 Btu’s for each kilowatt of power consumed.

Dehumidifiers are rated by the amount of water removed, divided by power input. A rating of 240 pints per day with power requirements of 1 kW, yields 10 pints per kW.

If COP is calculated for dehumidifiers, “Useful Heat” to the room is water condensed, minus excess heat added. Each hour, condensing 10 pints of water requires about 10,000 Btu’s of cooling (heat of vaporization/fusion). If 10,000 Btu’s of heat is also added the air, the net result is a COP of ZERO. For each kilowatt of power consumed, no net heat is removed from the room.

Larger climate control packages may use hot-gas to temper (reheat) cold, dehumidified air. Overall package size must be increased to account for reheating air during lights-off and lights-on.

Controlling temperature and humidity separately can yield a simple, energy efficient climate control system. Temperature control with standard air conditioner/heat pump packages provides a technician and parts friendly, reliable means to heat and cool a space. Splitting to two smaller packages is only slightly more expensive and provides the security of redundancy along with variable compressor capability without the complexity of digital scroll compressors and valves.

Water In = Water Out 100 gallons per day watering = 800 pints per day dehumidification

Daily water use and desired lights-off minimum room temperature during flower determines dehumidifier size. Refrigerant dehumidifiers lose water removal capacity in cooler, drier rooms. Less water vapor is in the room air, so less can be removed. Like wringing out a wet rag versus wringing out a damp rag.

Increasing dehumidifier COP reduces room heat load. Less heat means smaller air conditioner(s) and less electric use.

Subcooled 550 Hybrid dehumidifiers remove up to 550 pints of water per day (AHAM 80F, 60%rh) and provide 3 tons of cooling during lights-on. Up to 50% less room heat, results in a smaller air conditioner. Lights-off reheat delivers neutral (near 75 degrees F) dry air.

The Subcooled 550 Hybrid dehumidifier delivers cooling during lights-on and on-demand reheat during lights-off. This hybrid design yields a COP during lights-on of up to 15,000 Btu’s per kilowatt. Flower room cooling offers the greatest benefit for energy efficiency from the 550 Hybrid model.

The Subcooled 705 dehumidifier also delivers cooling during lights-on and on-demand reheat during lights-off. The high-water removal design yields a COP during lights-on of up to 9,000 Btu’s per kilowatt.

In both cases Subcooled Air dehumidifiers control humidity and allow you to use smaller air conditioners.

The cost of a Subcooled dehumidifier, condenser and room air conditioner is up to 20% lower than standard air conditioner and plug-in dehumidifiers. Power consumption is up to 15% lower.

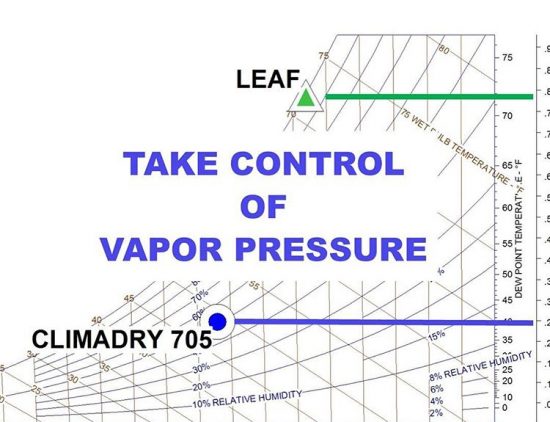

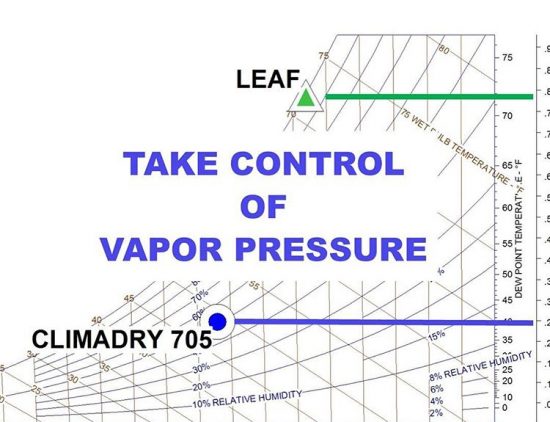

Vapor Pressure Deficit is an agricultural concept that measures the difference in pressure between the humidity inside and outside of a leaf. For cannabis growers, getting a handle on this metric can yield healthier, more robust plants. Controlling VPD can enable growers to increase water and nutrient intake, and as a result, increase and optimize plant growth. In addition to encouraging plant health, understanding VPD lets growers better regulate the surrounding plant environment to keep pests at bay. Large vapor pressure deficit pulls moisture from the flowers.

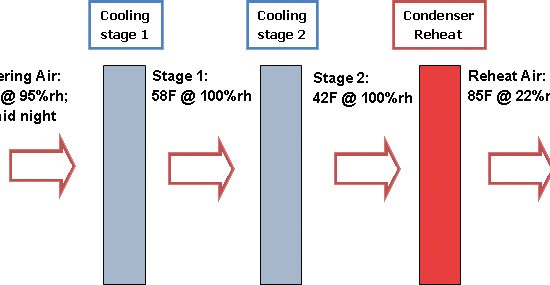

Condenser reheat coil. Warm air gets pulled in and cycled over cold coils. By using condensation, the coils pull moisture from the air which remains on the coils and drips into the dehumidifiers reservoir. Then the cold dry air gets reheated and exhausted back into the room.

Condenser reheat coil. Warm air gets pulled in and cycled over cold coils. By using condensation, the coils pull moisture from the air which remains on the coils and drips into the dehumidifiers reservoir. Then the cold dry air gets reheated and exhausted back into the room.

In our Subcooled 705 dehumidifier’s electric panel, a “Night Thermostat” senses ambient air temperature and automatically turns on reheat for you. The factory setting for this is 72F. So when the lights go off, the room starts cooling with the absence of heat from the lights, along with the cooler night temperatures. The Subcooled 705’s thermostat sensor will cool down to 72F, then the reheat feature turns on at that point. No more cold air issues at night! We take care of this for you.

By raising the set point to 77F. Reheat turns on when the room cools to 77F. Spikes will be minimized because the room cools slower after the lights go out.

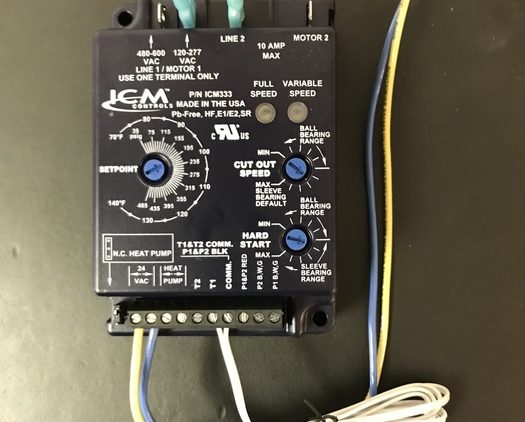

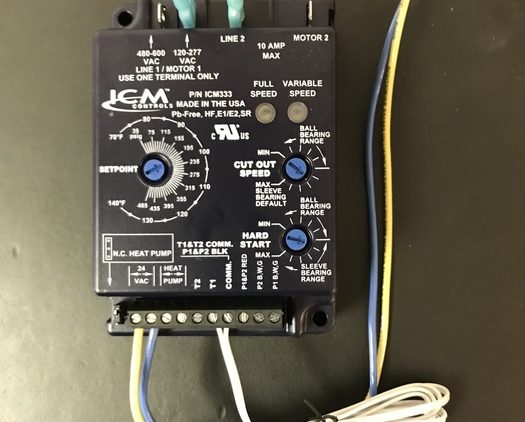

Dehumidifier air temperature can be adjusted up or down by installing a “head pressure controller” on the outdoor, 5 ton condenser unit. Results of recent testing are listed below. Delivering night air in the upper 70’s and lights- on air near 70 degrees F is available from Subcooled 705 and Climadry 705 dehumidifiers.

Also see our Tech Bulletin 333: How to Change Supply Air Temperature

P trap installation is critical for the proper drainage from the Subcooled 705 Dehumidifier.

The photo on the top shows an installation that is not recommended, the bottom photo shows a good drain line installation. As air is pulled through the blower a slight vacuum is created in the dehumidifier. The P-trap prevents outdoor air from being pulled through the drain line impeding water drainage from the unit. If enough water backs up in the unit, it starts leaking out all over the place.

Blowing cold air over plants when lights are off is a problem. Our Subcooled Air Growroom Dehumidifiers are designed to switch from cool air to warm, dry air. When lights turn off, the room cools. An on-board reheat thermostat switches the dehumidifier from cool to warm supply air. If not installed properly, the dehumidifier always blows cold air.

Solution:

Subcooled Air Growroom Dehumidifier units extract reheat from liquid refrigerant flowing to the dehumidifier. Maintaining 100 degree Fahrenheit liquid temperature at the condenser is easily done with a head pressure controller or low ambient kit. These devices slow down condenser fan speed to regulate liquid refrigerant pressure or temperature. Several inexpensive controller models are available (Headmaster, ICM333, Bayloam). For a quick check of your Subcooled Air 705 Dehumidifier, grab the 3/8″ copper liquid line entering the dehumidifier. If it is warm (body temperature) you’re good! If the line feels cool (below 95F) little heat is available in the refrigerant, so less reheat is delivered.

A customer with five 705 Subcooled Air grow room dehumidifiers was having drainage issues with one unit. Units were located in mechanical area above grow rooms. Metal ductwork installed in and out of dehumidifier. Filter racks installed in ceiling return ducts. It turned out that the factory air filter had not been removed or changed since installation a year ago. The filter had plugged air flow, causing freeze problems and allowing water to pour out of front of dehumidifier. Filter removed, no more problem.

Sealing cannabis grow rooms and ductwork are crucial steps to minimize climate control costs. Summer heat and humidity puts equipment to the test. High day and night outdoor dew point temperatures add to water removal requirements unless the room (walls, ceiling, floor) and HVAC system are perfectly sealed to eliminate air infiltration. Differences between room and outdoor air pressure also contribute to infiltration moisture and heat loads.

Infiltration measures the volume of outdoor air that seeps into the room or HVAC system. Air conditioners are forced to use more capacity on moisture removal, reducing sensible cooling capacity. Summer air infiltration increases energy costs and HVAC/dehumidifier equipment requirements. Quality construction practices are imperative, or you will pay for it in monthly energy costs.